The influence of torque on stress points for Hinge Bracket

Torque: this is related to uncontrolled scores output minlength in atoms[wv-from-latency length=”?” minlength = “3″] The twisting force which causes an object or a system to rotate around an axis | the torque comes on every rotating body and produces changes. The bracket is the weakest point of any hinge and when torque is applied to a brinket, its become tensile at various points. We can use torque sensors to quantify the amount of torque being applied to the bracket, and thereby measure where these stress points are. By having this information we can reinforce those lower areas of the bracket so that they do not break or wear out as fast. We look at how torque effects the stress points of our hinge brackets to make sure they are durable and last.

How Torque Sensors and Hinge Bracket Life Are Related

Torque sensors are very important for the durability of hinge brackets. This allows us to predict how long the brackets will last and when they might need replacing by continuously tracking the torque being applied to them during use. Knowing this helps us avoid carrying too much activity on the brackets and, consequently, keeping them safe from damage and reducing wear over time. Knowing how a torque sensor could end up damaging the hinge bracket, we can make ensure our brackets are robust and reliable.

Optimizing hinge bracket performance with torque sensor applications

We can analyze the performance of hinge brackets under different scenarios by using torque sensors. This information allows us to hone the quality of the brackets and locate various aspects that require improvements. This will allow us to make any necessary changes to improve the strength and durability of brackets. They also help us amplify the efficiency, and effective output of hinge bracket performance using inputs captured through torque sensors helping them perform to the best over extended periods.

How do torque sensors help to determine the load points of a hinge bracket?

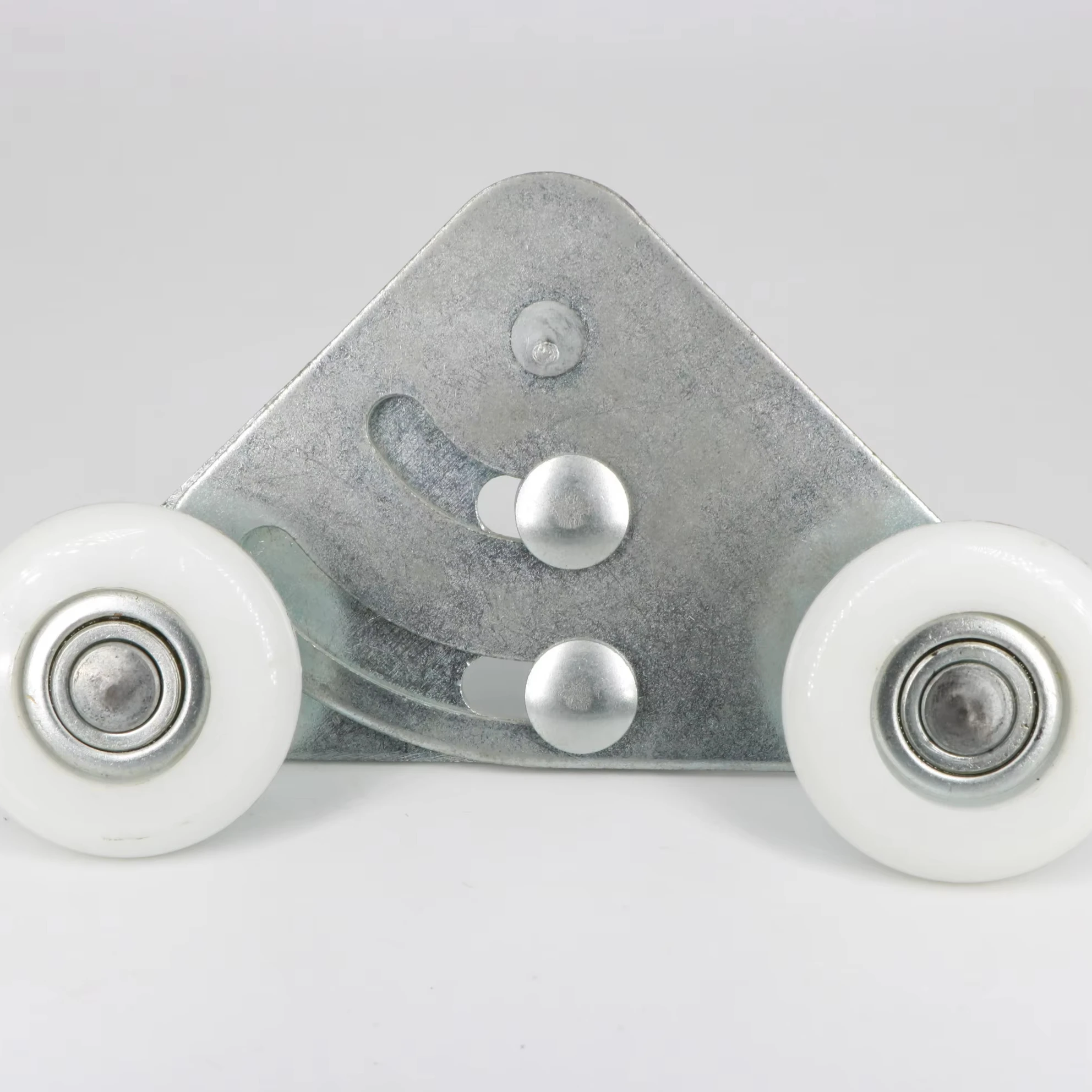

Torque Sensors are also used in the measurement of significant stress points of hinge brackets. These sensors allow us to identify the places with garage door assembly the highest stress and are more possible point of preventable failure on a bracket. And we reinforce those weak spots by analyzing this data, and try to ensure that they do not break. This proactive method to maintenance is what helps to keep the brackets strong and reliable no matter how often you use them. Having the ability to understand key stress points on hinge brackets as torque sensor or identified likely to fail can go a long way in preserving bracket integrity.

How to use torque sensor data to improve the lifespan and reliability of a hinge brackets

The lifecycle and reliability of hinge brackets can be increased using torque sensor data. This data will show us the wear and tear on the brackets throughout time allowing preventive measures garage door roller assembly to be taken in order to give some longevity with these brackets. It lets us study the stress patterns of the brackets to enable themselves for a better preventer over their damage. This proactive maintenance strategy simply means that the stress braces are well maintained, operating fine over an extended period. Characteristics that allow to utilize torque sensor data for improving the life of hinges, bracket reliability.

To sum up, torque sensors are useful for analysing the function of hinge brackets. With the aid of this study, we can ensure that our brackets are inherently strong while maximizing performance by knowing where it is possible to design garage door nylon roller around and how sensor data helps us understand torque. Cultivated from the latest and accurate technology we are pledged to channelizing the premium quality and flawless performance via our products which is led by torque sensors. This technology allows us to keep providing high-quality hinge brackets for our customers.